ReliaMaint CMMS Power features

Workflows

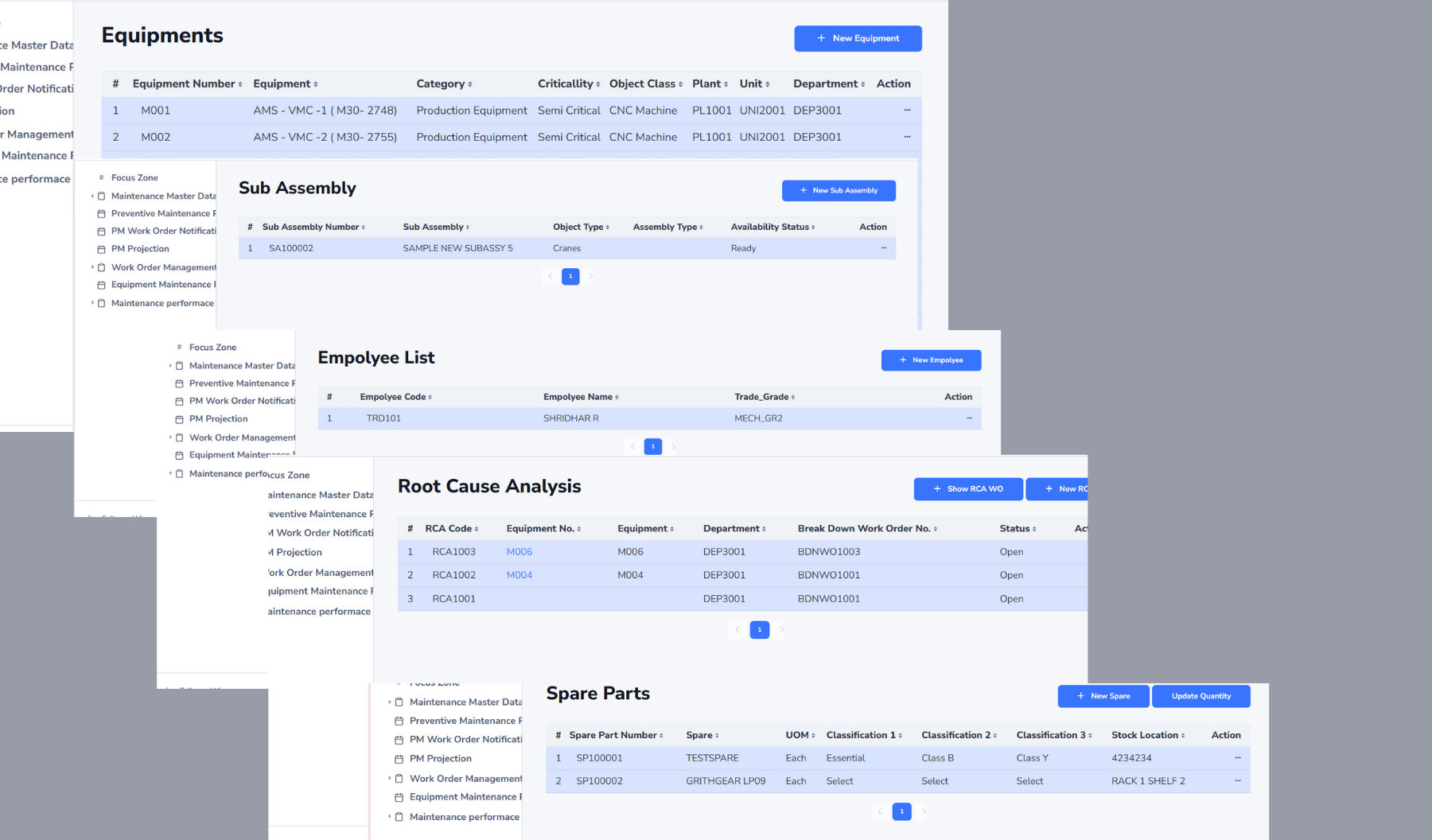

01Asset Register

A CMMS maintains a comprehensive asset register, which serves as a centralized database containing detailed information about all assets within an organization.The asset register provides a holistic view of the organization's asset inventory, facilitating effective asset management and decision-making processes.

02Asset Hierarchies

CMMS allows for the creation of asset hierarchies, which represent the relationships and dependencies between different assets within an organization. Asset hierarchies define parent-child relationships, grouping assets into logical structures such as equipment systems, production lines, or geographical locations.

03Work Order Management

Users can create, prioritize, assign, and track work orders for maintenance tasks. Work orders may include details such as the type of maintenance required, parts needed, labor hours, priorty,Fault code, RCA triggersss and scheduling.

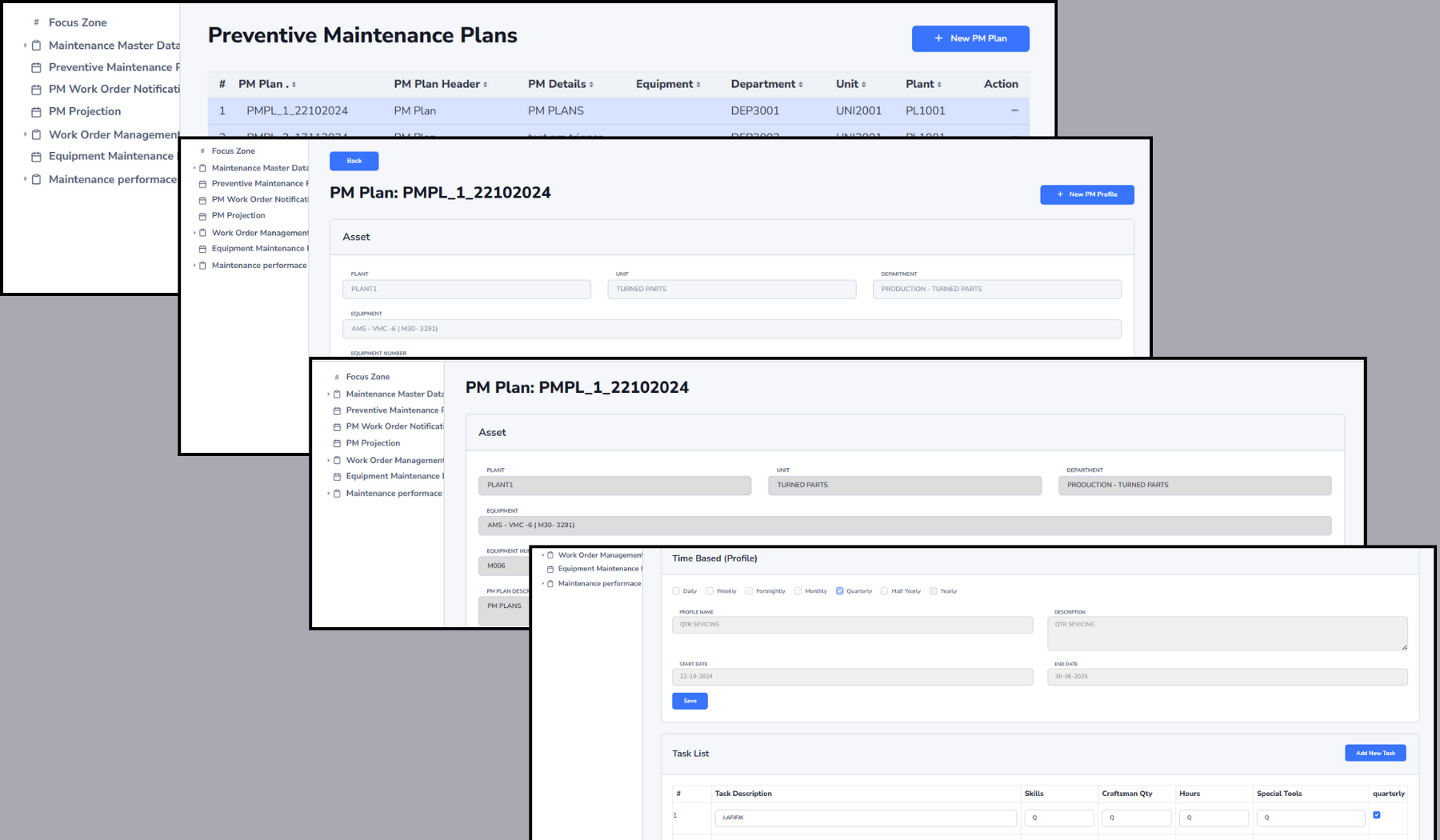

04Preventive Maintenance Scheduling

CMMS enables the scheduling and automation of preventive maintenance tasks based on predefined criteria such as time, usage, or condition. This helps in reducing downtime, extending asset lifespan, and preventing costly breakdowns.

Analytics

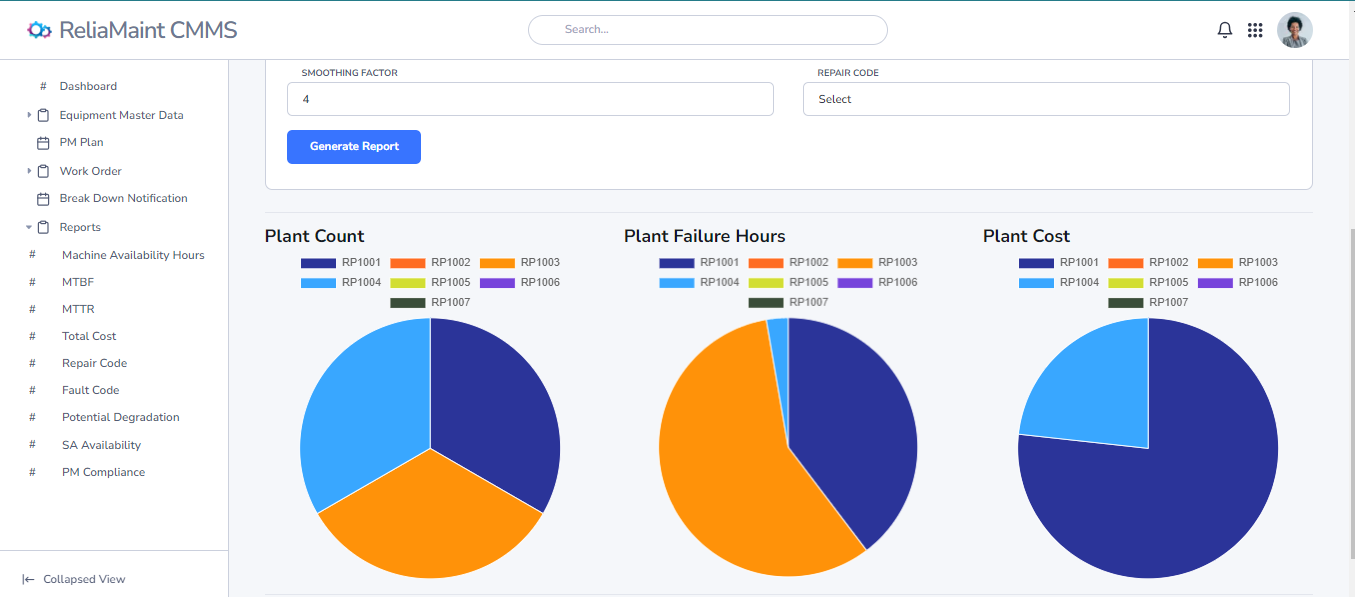

01Equipment Downtime Tracking

**Equipment Downtime Tracking**: CMMS provides insights into equipment downtime by recording the duration and reasons for downtime events. This data helps in identifying recurring issues, improving maintenance strategies, and minimizing production disruptions.

02Reporting and Analytics

CMMS generates reports and analytics on various maintenance metrics such as equipment performance, maintenance costs, work order completion rates, and inventory usage. These insights aid in decision-making and continuous improvement efforts.It provides a centralized database of asset information.

03Inventory Management

It allows users to manage inventory levels of spare parts, tools, and consumables necessary for maintenance activities. CMMS can track stock levels, reorder points, and inventory usage, optimizing inventory control and reducing stockouts.

04Mobile Access

It offer mobile applications or responsive web interfaces, allowing technicians to access work orders, update maintenance activities, and record asset information from smartphones or tablets while in the field.

Functional Demo

How We Collaborate With You

It typically involves identifying areas of improvement, optimizing processes for efficiency, and ensuring compliance with industry standards. It provides actionable insights for enhancing asset reliability, minimizing downtime, and maximizing productivity.

Analyzing current workflows, designing optimized processes, and mapping them within the CMMS while ensuring adequate technical support for system integration and troubleshooting challenges that may arise during implementation.

Our training emphasizes understanding asset reliability, maintenance management principles and how to leverage the full potential of your CMMS, exploring its features and functionalities to streamline maintenance.

Refresher training, performance monitoring, feedback collection, regular check-ins, and access to documentation. Tailored to organizational needs, it ensures smooth CMMS utilization, addresses challenges promptly, and maximizes user proficiency, facilitating efficient maintenance management.